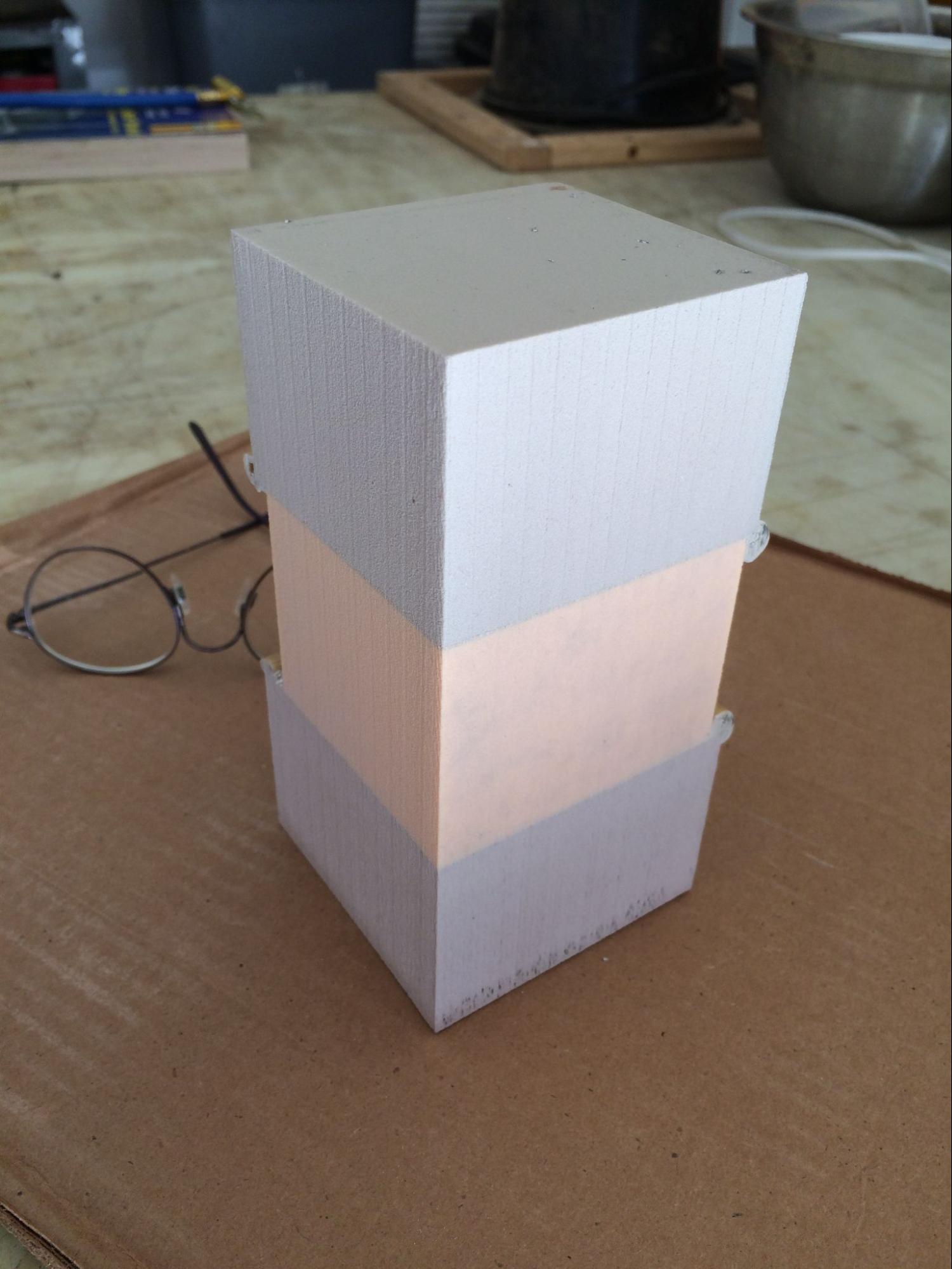

Evaluating resin infusion flow media.

The yellow media retains more resin than the red.

We have represented a lot of composite material and process equipment manufacturers over the past 30+ years and we have seen what works (and what doesn’t work). In the process of marketing and selling their products, some manufacturers can be “optimistic”. The last thing any company wants to do is commit their precious capital budget to a “beta test” technology.

The following scan shows an Embraer EMB145 radome and repair mold.

This job required that we first visit with the customer and examine the part (radome) that they were trying to repair. Southbrook Technologies personnel later returned and spent several days training customer composite technicians how to plan, set-up and build the required radome repair mold. Economics are such that a good bond repair mold will often pay for itself with the first repair part.

The yellow media retains more resin than the red.

High temp carbon epoxy acoustic guitar mold being laid up on CNC machined aluminum master model. Waiting for the surface coat to “tack”, prior to lamination.

No job is too small for composite tooling and sometimes an oven, press or autoclave is not even needed.

Shown here are a set of bladder molding tools. The part is laid up on an elastomeric bladder and the tool is assembled around the bladder.

When the bladder is pressurized with compressed air, the laminate is tightly consolidated. Great parts can be cured with wet resin at room temperature, or with pre-preg materials in an oven.

This one is for a parabolic reflector.

Urethane tooling board is often marketed for high temp applications. It can become unstable at temperatures above about 200F. This 400F test sample has bowed 0.040” in the middle.

Tooling board materials are great for low temp (<200F) master models, as long as you glue them up properly. Every gap in the glue line between boards is a potential vacuum leak.

Any geometry can be successfully infused, as long as you can pull at least 26” of leak free vacuum and the master model is dimensionally stable. This master was 3D printed.

An R&D manager at one of the major archery companies once told me that you could not build bow limbs out of carbon fiber, due to its extreme stiffness. Using a dropped ply schedule of 3K unidirectional carbon fiber tape and 3K plain weave fabric, these bow limbs were autoclave cured at 45PSI. 50 pound draw weight and 200 FPS arrow velocity.

Cost to our customers for consulting services is $85.00 per hour, plus actual travel and material expenses. We provide written estimates and detailed billing, along with receipt documentation.

Get in Touch